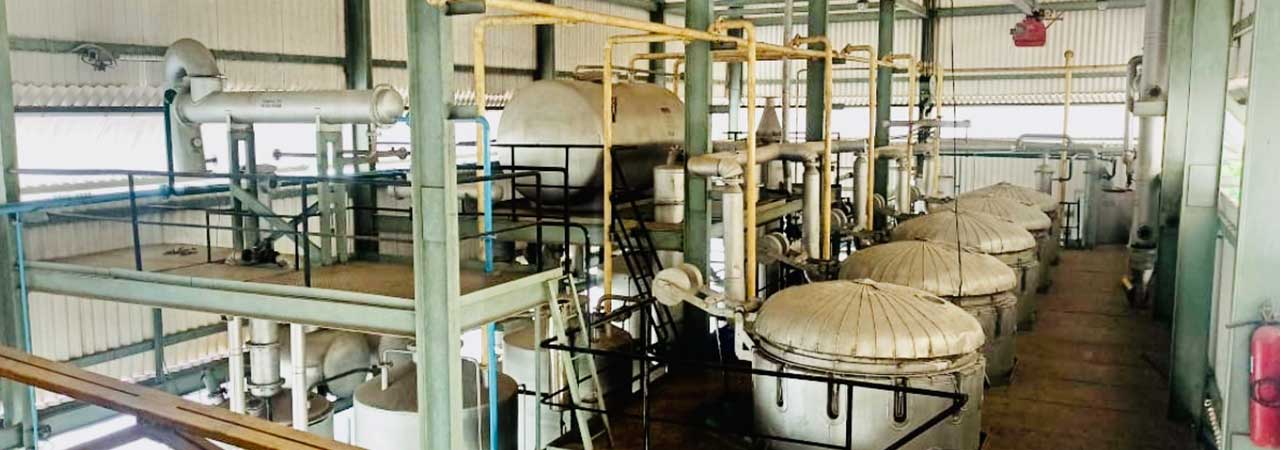

Manufacturing Process

Since we know that the floral extraction is most delicate one. We have designed our plant by renowned scientists who have got experience of more than forty years in the field of designing solvent extraction plants. Our plant is equipped with highly sensitive technology to preserve the delicate fragrances of flowers and this technology is nowhere adapted in whole of India for the production of fragrances

Highlights

Our plant is situated in 14 acres of land and our flower processing plant has the capacity to process 15 tonnes of flowers per day.

We have got two Absolute processing plant one is a Bigger Plant, in which we can process up to 275 Kgs of Concrete Per Month and a pilot plant in which we can process 50 Kgs of concrete per month.

We have designed a highly delicate process to manufacture absolutes which would preserve the 100% natural odour of the flowers, this technique is not used by any of our competitors.

We have set up a Pilot plant to manufacture the rare variety of flowers in a smaller scale in which we can manufacture 500-600 kgs of flowers per day.

We use food grade solvent & perfumery grade alcohol for manufacturing the products

We give utmost priority to the quality of flowers. For this we have tied up with farmers for the procurement of fresh flowers.

Storage is very important factor, which affects the stability of products. For this we have taken utmost care to preserve the fragrance of the products. For this our company is equipped with cold storage room.

Our company is equipped with a strong R&D team and QC & QA team.

Our facility is provided with uninterrupted power supply.